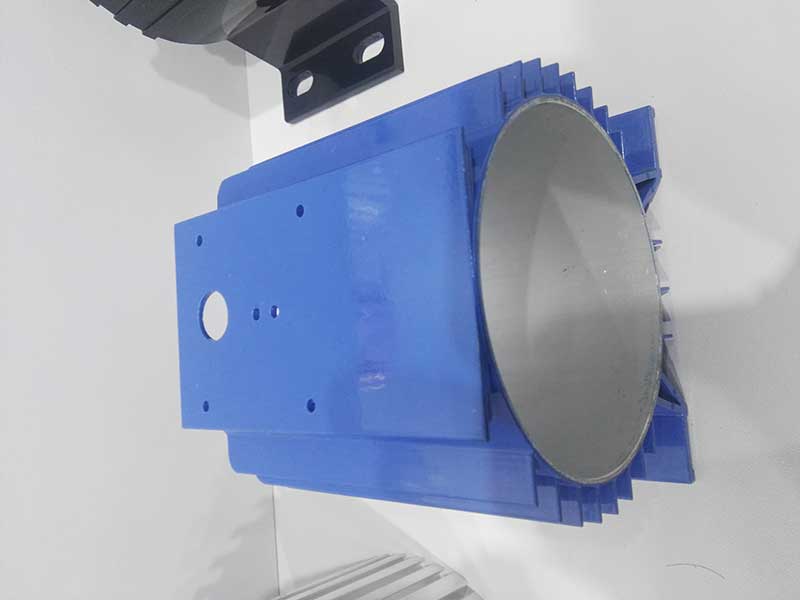

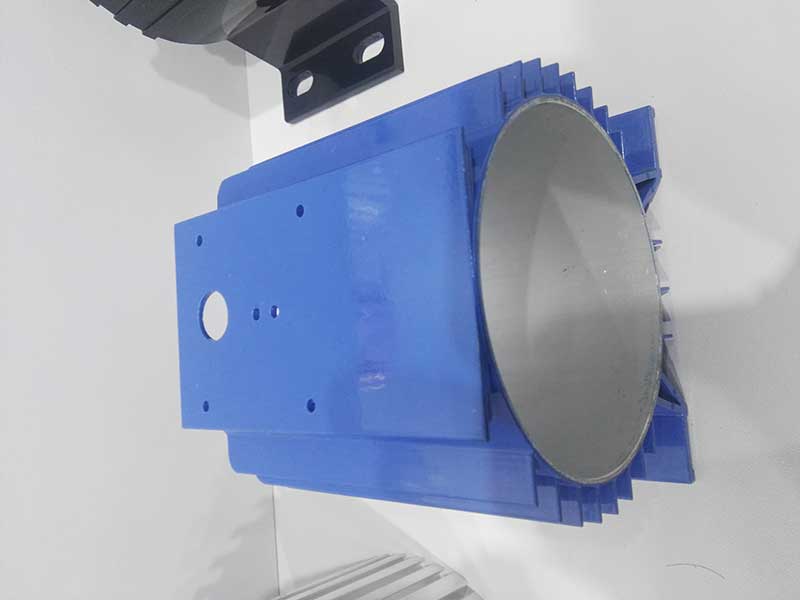

The aluminum profile motor shell is widely used. The air cooled aluminum motor shell produced by Henan Chalco has the advantages of high strength, light weight and good heat dissipation performance. Moreover, it is also beautiful and generous on the surface, not only corrosion-resistant, but also does not need any cutting for the inner bore. Not only the volume is small and the weight is very light, the structure is relatively simple, the installation and maintenance are very convenient, the production process is also very environmental protection, and the production efficiency is relatively high, the transportation and storage are also more convenient, so it is also favored by the majority of motor manufacturers.

1. Specs:

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

Mill finish surface:

Color anodized surface:

Color Painted surface:

1. Specs:

| Item | Alloy | Temper | Surface | Usage |

| Common aluminum motor shell, inner hole non cutting motor shell | 6063、6063A | T5、T6 |

|

Non explosion proof motor |

| 6063 | Non explosion proof motor |

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

| Alloy | Chemical component(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | ||

| Each | Total | |||||||||||

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063A | 0.30-0.6 | 0.15-0.35 | ≤0.10 | ≤0.15 | 0.60-0.9 | ≤0.05 | ≤0.15 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

Mill finish surface:

Color anodized surface:

Color Painted surface: