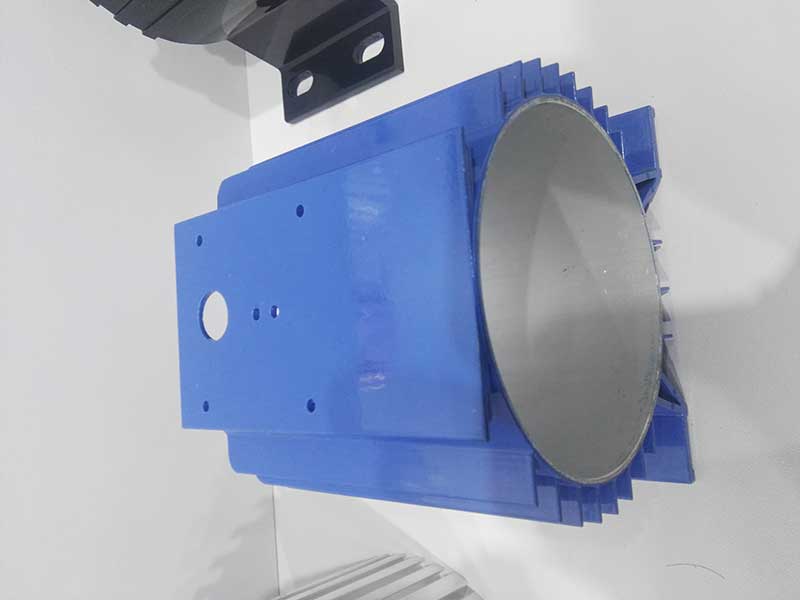

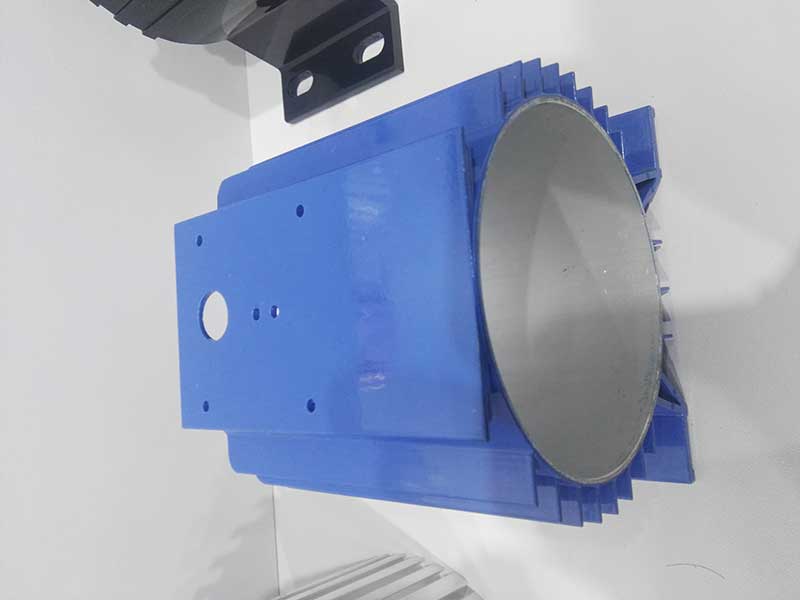

The horizontal non cutting aluminum motor shell produced by Henan Chalco is suitable for supporting shells in various industries such as motor, fan, water pump, air conditioner, mechanical equipment and electric work. The product has the advantages of light weight, high strength, good heat dissipation and thermal conductivity, high tensile strength and beautiful appearance after being used in developed countries in Europe and America.

The inner hole has eight precision and the hardness has reached T5 state. It can install the split directly, which avoids a lot of waste caused by the traditional aluminum motor case inner hole cutting, and can cut the length freely, saving 20% aluminum material and greatly reducing the cost.

1. Specs:

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

Mill finish surface:

Color anodized surface:

Color Painted surface:

The inner hole has eight precision and the hardness has reached T5 state. It can install the split directly, which avoids a lot of waste caused by the traditional aluminum motor case inner hole cutting, and can cut the length freely, saving 20% aluminum material and greatly reducing the cost.

1. Specs:

| Item | Alloy | Temper | Surface | Usage |

| Common aluminum motor shell, inner hole non cutting motor shell | 6063、6063A | T5、T6 |

|

Non explosion proof motor |

| 6063 | Non explosion proof motor |

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

| Alloy | Chemical component(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | ||

| Each | Total | |||||||||||

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063A | 0.30-0.6 | 0.15-0.35 | ≤0.10 | ≤0.15 | 0.60-0.9 | ≤0.05 | ≤0.15 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

Mill finish surface:

Color anodized surface:

Color Painted surface: