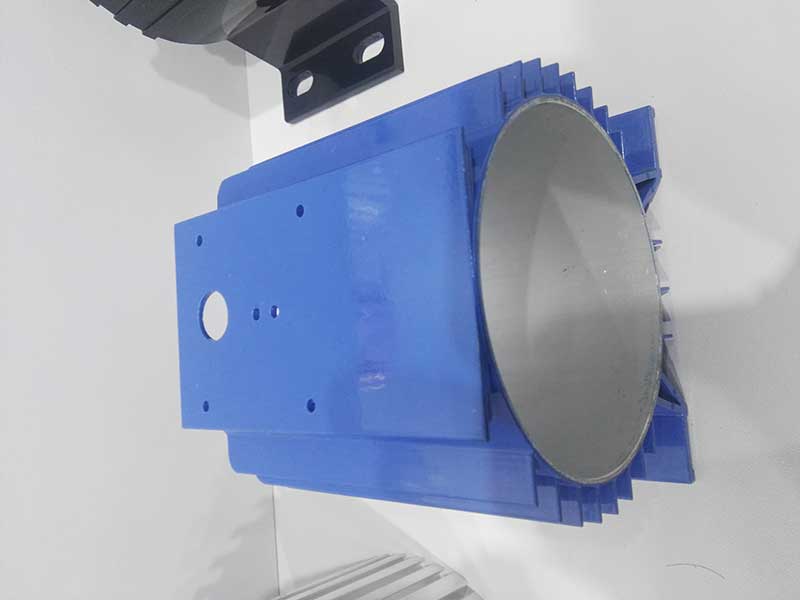

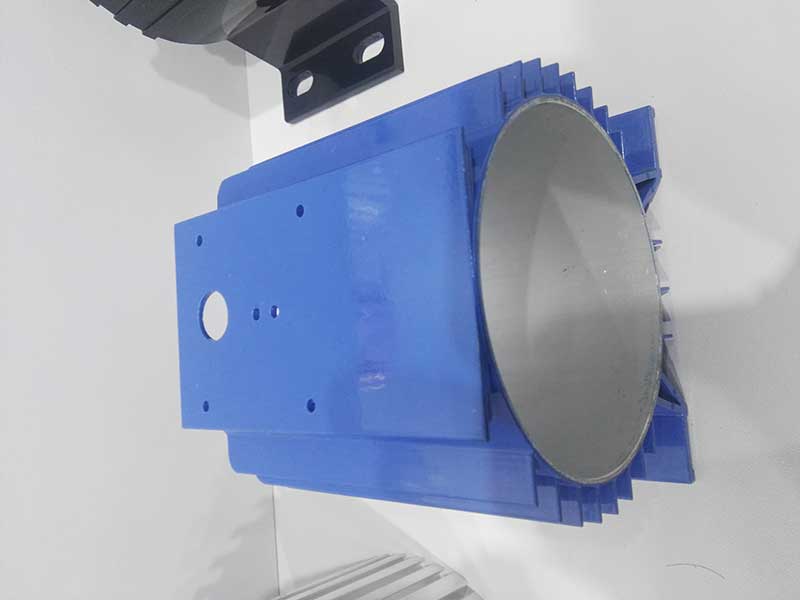

The extruding vertical aluminum motor shell produced by Henan Chalco is mainly installed on the motor. Chalco extruding aluminum motor shell products have the characteristics of accurate material and chemical composition, small form and position tolerance, and small processing dimension tolerance. Therefore, the operation efficiency, noise and service life of the motor are significantly improved compared with the ordinary motor shell.

1. Specs:

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

Mill finish surface:

Color anodized surface:

Color Painted surface:

1. Specs:

| Item | Alloy | Temper | Surface | Usage |

| Common aluminum motor shell, inner hole non cutting motor shell | 6063、6063A | T5、T6 |

|

Non explosion proof motor |

| 6063 | Non explosion proof motor |

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

| Alloy | Chemical component(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | ||

| Each | Total | |||||||||||

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063A | 0.30-0.6 | 0.15-0.35 | ≤0.10 | ≤0.15 | 0.60-0.9 | ≤0.05 | ≤0.15 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

Mill finish surface:

Color anodized surface:

Color Painted surface: