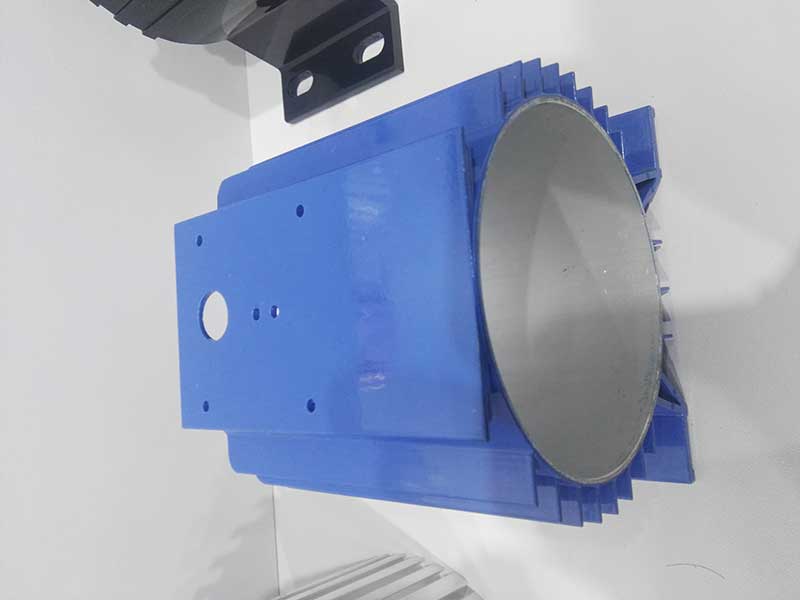

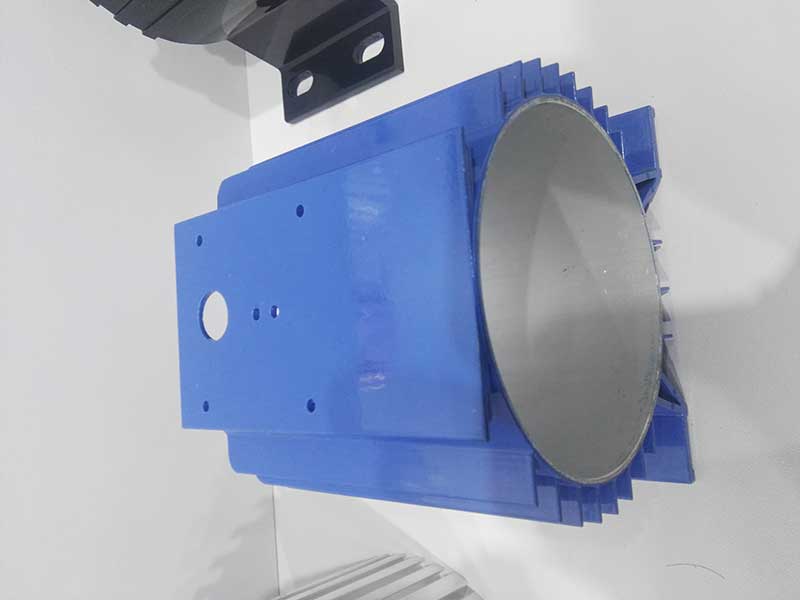

The aluminum shell with high heat dissipation efficiency for the servo motor includes the shell body with a tubular structure, the inner center of the shell body is provided with a mounting hole, the outer sides of the shell body are respectively provided with a mounting boss, a connecting piece, a reinforcing rib and a heat dissipation fin along the axial extension of the shell body, the top of the connecting piece is provided with a mounting groove, and the reinforcing rib is provided with a saw tooth structure. The aluminum shell for servo motor produced by Henan Chalco is installed on four sides, which increases the fin layout area and improves the heat dissipation efficiency; the shell is made of aluminum material, which reduces the overall weight of the motor and reduces environmental pollution.

Application: widely used in AC, DC motors, servo motors, new energy electric vehicles and other fields.

Material: 6063

Composition standard: GB / T 3190-2008 chemical composition of deformed aluminum and aluminum alloy

Product standard: GB / t6892-2006 aluminum and aluminum alloy extruded profiles for general industrial use

Casing deep processing standard:

Tolerance of inner diameter and stop: < 0.05mm;

Concentricity: < 0.05mm;

Out of roundness: < 0.05mm;

Length: ≤ 0.1mm

Shell product specification (maximum)

Maximum outer circle diameter of ordinary motor: Φ 360mm;

Water cooled motor: Φ 600mm

1. Specs:

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

Mill finish surface:

Color anodized surface:

Color Painted surface:

Application: widely used in AC, DC motors, servo motors, new energy electric vehicles and other fields.

Material: 6063

Composition standard: GB / T 3190-2008 chemical composition of deformed aluminum and aluminum alloy

Product standard: GB / t6892-2006 aluminum and aluminum alloy extruded profiles for general industrial use

Casing deep processing standard:

Tolerance of inner diameter and stop: < 0.05mm;

Concentricity: < 0.05mm;

Out of roundness: < 0.05mm;

Length: ≤ 0.1mm

Shell product specification (maximum)

Maximum outer circle diameter of ordinary motor: Φ 360mm;

Water cooled motor: Φ 600mm

1. Specs:

| Item | Alloy | Temper | Surface | Usage |

| Common aluminum motor shell, inner hole non cutting motor shell | 6063、6063A | T6 |

|

Non explosion proof motor |

| 6063 | Non explosion proof motor |

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

| Alloy | Chemical component(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | ||

| Each | Total | |||||||||||

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063A | 0.30-0.6 | 0.15-0.35 | ≤0.10 | ≤0.15 | 0.60-0.9 | ≤0.05 | ≤0.15 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

Mill finish surface:

Color anodized surface:

Color Painted surface: