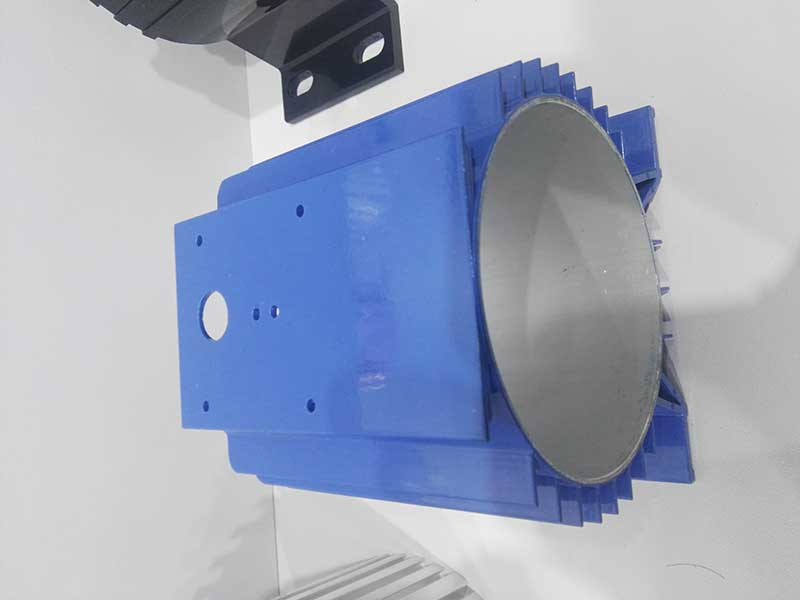

Aluminum Electric Motor Housing

News | 2020-03-19 17:54

Aluminum motor housing has the advantages of light weight, high strength, good heat dissipation, beautiful surface, corrosion resistance, no cutting in the bore, etc. Because of the poor concentricity between the shell and the end cover in the traditional processing of Aluminum electric motor housing, the running noise of

aluminum electric motor housing is large. According to the machining method of aluminum electric motor housing, a machining tool for

aluminum electric motor housing is designed. The aluminum electric motor housing can be processed by two end stops of the aluminum electric motor housing after one clamping. The concentricity of the inner hole of the aluminum electric motor housing can reach 0.02mm, and the production efficiency can be increased by more than one time, which solves the problem of large noise of the

aluminum electric motor housing.

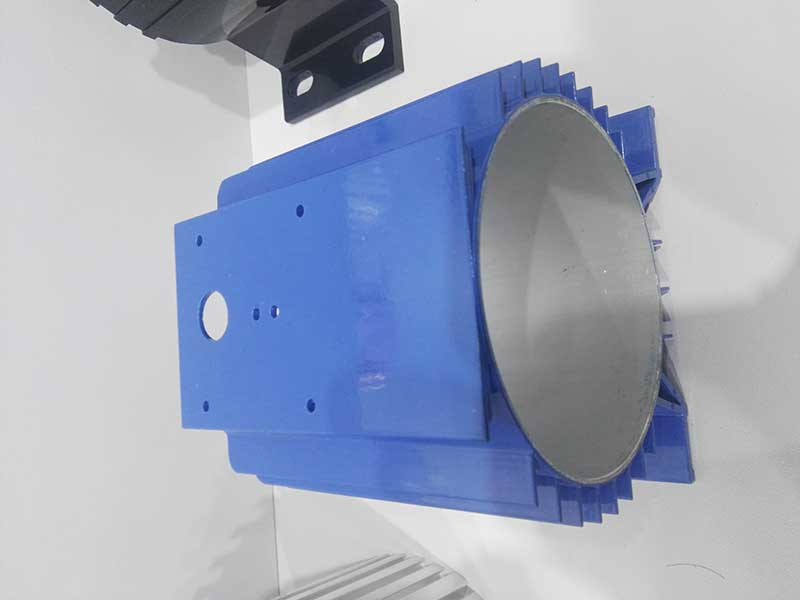

The quality of

aluminum electric motor housing mainly includes appearance quality, appearance quality and application quality. Appearance quality refers to the surface finish, surface defect, size deviation, style deviation and weight deviation of the casting; external quality mainly refers to the chemical composition, physical properties, mechanical properties, metallographic group of the casting, as well as the hole, crack, doping, segregation and other conditions existing in the casting; application quality refers to the long experience of the casting in different conditions, covering wear resistance , corrosion resistance, chilling heat resistance, fatigue, shock absorption and other performance as well as grindability, weldability and other process performance.