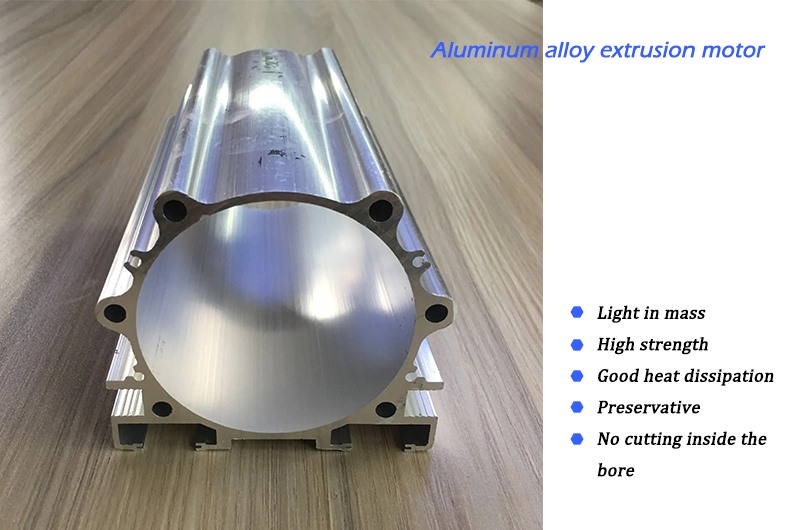

The aluminum alloy extrusion motor housing has the advantages of light weight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, no cutting in the bore, etc. Because of the poor concentricity between the housing and the end cover in the traditional processing of aluminum alloy motor housing, the noise of aluminum alloy motor housing is large. According to the processing method of aluminum alloy motor housing, a kind of aluminum alloy motor housing installation is designed. Using this tooling, two end stops of aluminum alloy motor housing can be processed at the same time after one clamping, which can improve the production efficiency by more than one time and solve the problem of large noise of aluminum alloy extrusion motor housing.

According to the composition and production process characteristics of aluminum alloy, it is generally divided into two categories: deformation and casting aluminum alloy. The main industrial applications are aluminum manganese, aluminum magnesium, aluminum magnesium copper, aluminum magnesium silicon copper, Aluminum zinc magnesium copper alloy is also called mature aluminum alloy. According to its composition and performance characteristics, it can be divided into five kinds: antirust aluminum super hard aluminum forged aluminum and special aluminum. Aluminum motor housing is mainly used in electric car motor, water-cooling motor, servo motor, frequency conversion motor and other aspects.