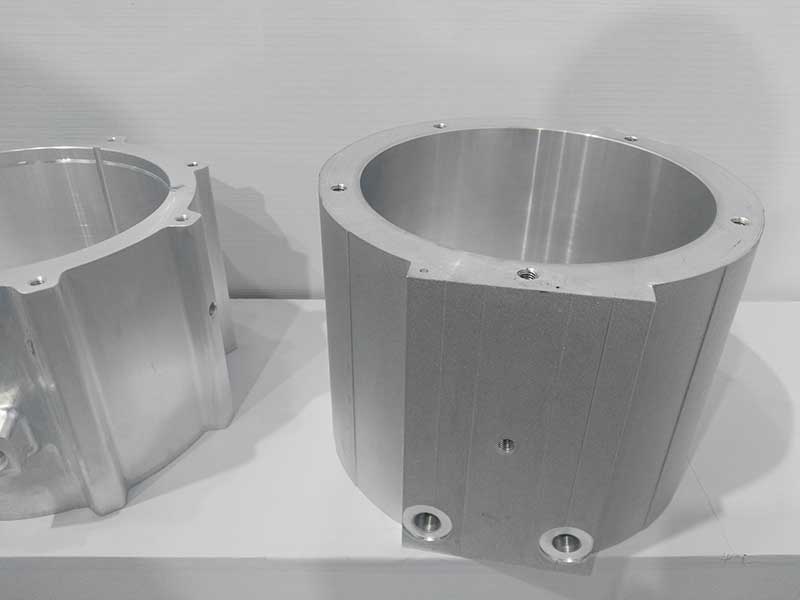

The hot extruded aluminum the motor housing has the advantages of light weight, high strength, good heat dissipation performance, beautiful and elegant surface, corrosion resistance, and free cutting of the inner chamber. Due to the poor concentricity between the housing and the end cover during the processing of the traditional aluminum motor housing, the aluminum motor housing is noisy. According to the processing method of the aluminum alloy motor housing, a motor housing aluminum profile installation is designed. Using this tooling can realize the simultaneous processing of the two end faces of the aluminum alloy motor housing after one clamping, which doubles the production efficiency. In the above, the problem of high noise of the aluminum alloy motor casing is solved.

Our other aluminum motor housing profiles are also used for: micro motor housing, motor housing aluminum profile, cooler motor housing, water-cooled motor housing, air compressor motor housing, negative pressure fan, motor housing, electric car motor housing , Tricycle motor housing, servo motor housing, injection molding machine motor, cooling tower motor, cylinder tube, axial fan motor, power tool motor, gear motor, etc. Our company has successfully developed unique processing tools for extruded and die cast aluminum products. Its deep processing quality occupies a prominent position in the field of deep processing of aluminum profile products for motor housings in China, and successfully solves the problems of springback deformation after adjustment of the inner hole of the aluminum motor housing and the misalignment that is prone to occur during the deep processing of products. Provide more perfect ultimate products for motor manufacturers