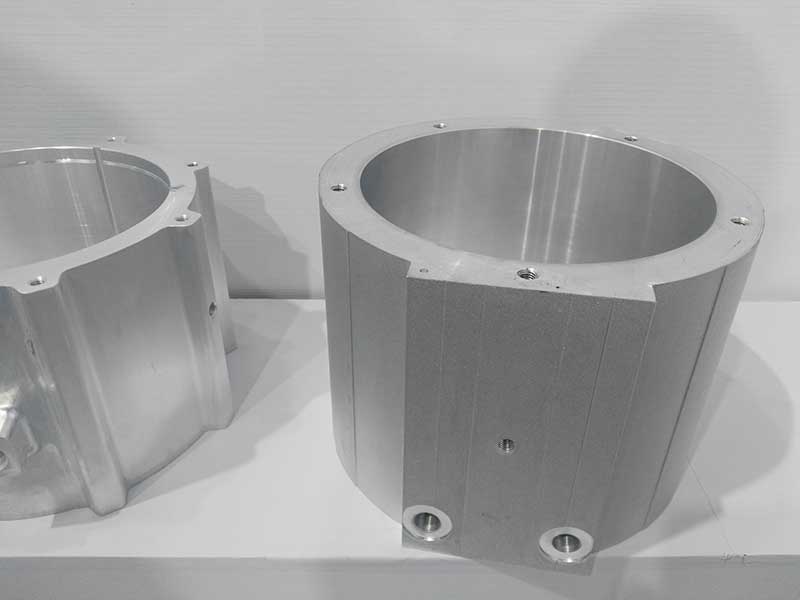

2. The extruded aluminum motor enclosure is light in weight. Due to the relative metal characteristics of aluminum, the motor accessories are light in weight. The product is more convenient for mechanical transportation and installation. It also greatly reduces the weight of the whole motor product.

3. Good product plasticity. Because of the special physical properties of aluminum alloy, the ductility and plasticity of products are much better than that of steel.

4. The extruded aluminum motor enclosure has the advantages of light weight, small vibration and low noise, as well as the features of water-proof, dust-proof and anti-corrosion, energy saving, high performance, high efficiency and long service life. It is a special new product of ordinary motor, environmental protection type.

5. Good heat dissipation.

Specification: 130 * 130

Meter weight: 7.6kg/m

Tensile strength: 210mpa

Thickness of oxide film: 12um

Hardness: 8-12hw