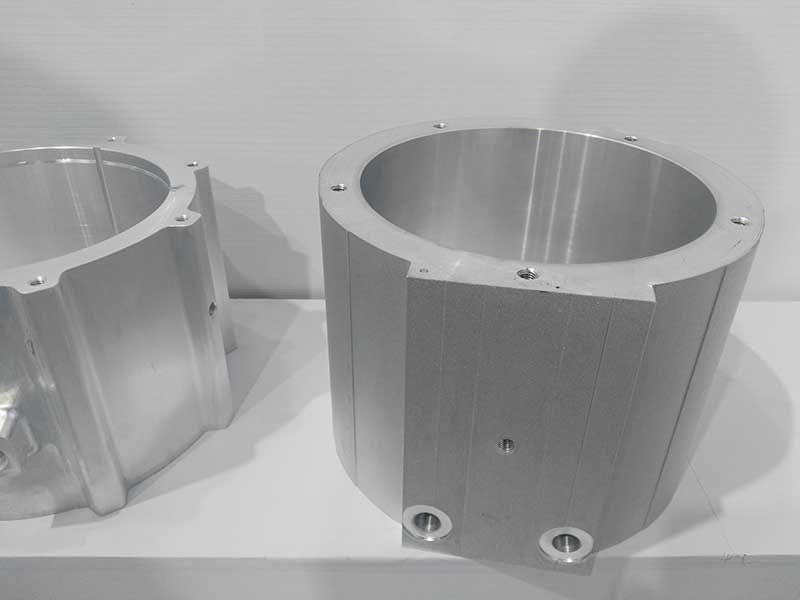

In terms of heat dissipation performance and cost, plastic has poor comprehensive performance. It is generally used for small built-in pumps with poor quality. Stainless steel is of medium performance and is used in both built-in pumps and external pumps. It is a kind of Aluminum extension motor body with high cost performance, while cast iron is more suitable for submersible sewage pumps, Water cooling is used to cool down. If it is used in an external pump, its heat dissipation performance will be greatly reduced, and the aluminum alloy with good comprehensive performance can use the design of fins to ensure good heat dissipation performance of the motor under dry operation, that is, the price is really expensive.