In fact, the main function of the shell in the motor is still in the mechanical aspect, which can be ignored in the magnetic conduction and circuit function. The general asynchronous motor is not very hot, only some rare earth permanent magnet synchronous motors will consider the heat dissipation performance, and the widely used in the market is basically asynchronous motor, so the aluminum motor The probability of body motor is lower than that of cast iron.

The motor links used in industrial places are relatively bad, such as vibration and fixation requirements are relatively high. Aluminum is softer than cast iron, so it's not suitable.

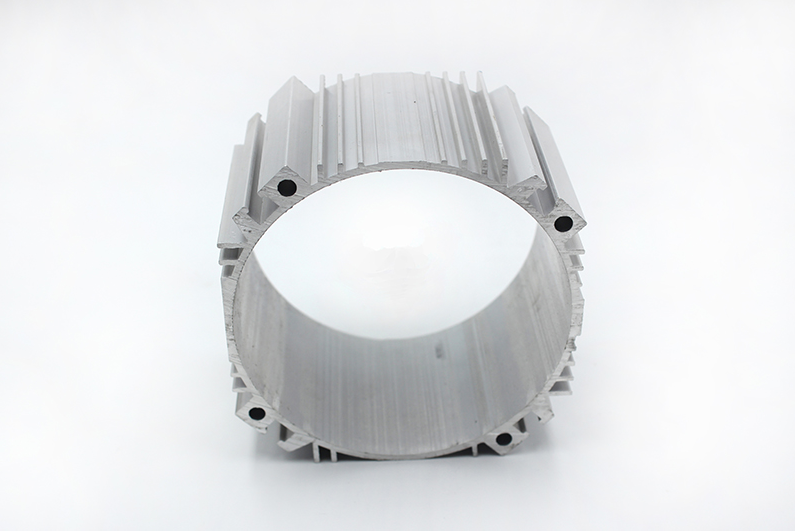

Aluminum motor body is light in weight, convenient in processing, good in extensibility, and better in plasticity than cast iron, but its price is expensive. Generally, asynchronous motors have to consider the cost. When the power is large and the volume is large, it is also a big expense.

In the case of low power and weight sensitivity, such as model aircraft, aluminum motor body motor has advantages.