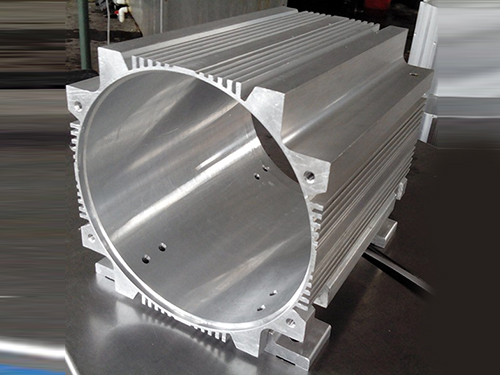

The motor housing extrusion needs to be clamped twice in the processing process, which increases the processing time of motor housing aluminum profile, thus affecting the production efficiency. Moreover, due to two times of clamping, it can not guarantee the parallelism of the aluminum profile of the motor housing, especially the parallelism of the two sections of the aluminum motor hosuing profile . During the use of the aluminum profile of the motor housing in the motor, due to the motor housing The poor parallelism of the two sections of the extrusion results in the poor concentricity of the housing and the end cover, which leads to the mechanical imbalance of the motor rotor of the aluminum profile motor of the motor housing, and the motor is easy to produce the bore sweeping, which is the main reason for the noise of the aluminum profile motor of the motor housing and affects the promotion of the aluminum profile motor housing.

The extruded aluminum motor housing has the advantages of light weight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, no cutting in the inner chamber, etc. Because of the poor concentricity between the housing and the end cover in the traditional aluminum profile processing of motor housing, the motor running noise of aluminum alloy housing is large. According to the machining method of motor housing extrusion, a machining tool for aluminum profile of motor housing is designed. The motor housing extrusion can be processed by two end stops of aluminum profile of motor housing after one clamping. The concentricity of inner hole of motor housing expansion is up to & le; 0.02mm, which can improve the production efficiency by more than one time, and solve the problem of large noise of motor of extrusion motor housing