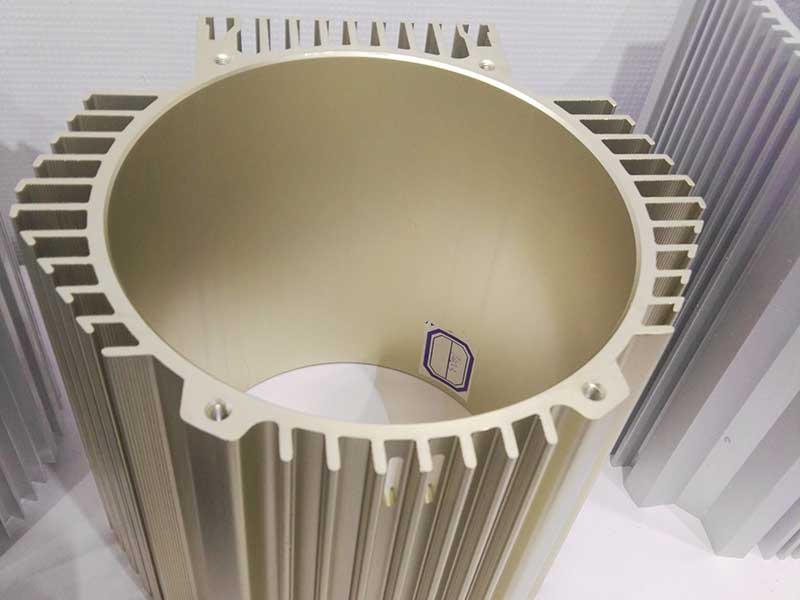

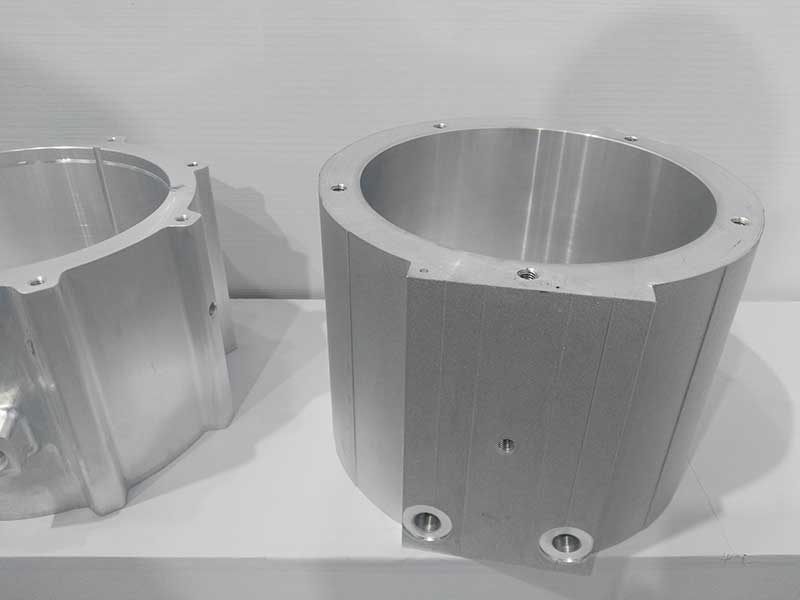

Common performance data of aluminum profile of motor shell:

Material brand: 6063-T5

Surface: untreated, anodized, electrolytic colored

Inner diameter working difference: ≤ 0.0007 D; roundness ≤ 0.0012d

The Aluminum extrusion motor housing produced by Henan Chalco are also used for: micro motor case, environmental protection air conditioning motor case, cooling fan motor case, water-cooling air conditioning motor case, air compressor motor case, negative pressure fan, motor case, electric vehicle motor case, tricycle motor case, servo motor special case, injection molding machine motor, cooling tower motor, cylinder, axial flow wind Machine motor, electric tool motor, reducer motor, etc.

Henan Chalco has successfully developed a unique special processing tool for extrusion products. Its deep processing quality occupies a significant position in the field of deep processing of motor housing aluminum profile products in China. It has successfully solved the problems such as springback deformation after adjusting the inner hole of motor housing aluminum profile and the unevenness in the process of deep processing of products, so as to provide a more perfect end for the majority of motor manufacturers Polar products.

1. Specs:

| Item | Alloy | Temper | Surface | Usage |

| Common aluminum motor shell, inner hole non cutting motor shell | 6063、6063A | T5、T6 |

|

Non explosion proof motor |

| 6063 | Non explosion proof motor |

The magnesium content of shell profile for explosion-proof motor shall be no more than 0.5%, and other requirements shall conform to the 6063 brand in GB / t3190-2008.

2. Chemical composition:

| Alloy | Chemical component(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | ||

| Each | Total | |||||||||||

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063A | 0.30-0.6 | 0.15-0.35 | ≤0.10 | ≤0.15 | 0.60-0.9 | ≤0.05 | ≤0.15 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

3. Tolerance of Dimensions

| Frame Size、Flange No | Inner Diameter(D) | The wall thickness of The inner hole(t) |

The wall thickness of Bottom foot(T) |

||

| The smallest wall thickness | Tolerance | The minimum wall thickness | Tolerance | ||

| 50 | 80 | 1.5 | +0.3 -0.1 | 2.8 | +0.3 -0.1 |

| 56 | 90 | 1.8 | +0.3 -0.1 | 3.0 | +0.3 -0.1 |

| 63 | 96 | 2.0 | +0.3 -0.1 | 3.5 | +0.3 -0.1 |

| 71 | 110 | 2.2 | +0.35 -0.1 | 4.0 | +0.4 -0.1 |

| 80 | 128 | 2.5 | +0.35 -0.1 | 4.5 | +0.4 -0.1 |

| 90 | 145 | 2.8 | +0.4 -0.1 | 5.0 | +0.5 -0.1 |

| 100 | 155 | 3.0 | +0.4 -0.1 | 5.5 | +0.5 -0.1 |

| 112 | 175 | 3.2 | +0.4 -0.1 | 6.0 | +0.5 -0.1 |

4. Average diameter and roundness of inner hole

| Frame Size、Flange No | Inner Diameter(D) |

Common motor shell housing Profiles Inner hole roundness |

Inner hole free-cutting motor shell housing Profiles |

|

|

Average value of inner hole diameter(D0) tolerance zone |

Inner hole roundness | |||

| 50 | 80 | ≤0.30 | 0.05 | ≤0.10 |

| 56 | 90 | ≤0.35 | 0.06 | ≤0.11 |

| 63 | 96 | ≤0.40 | 0.07 | ≤0.12 |

| 71 | 110 | ≤0.45 | 0.08 | ≤0.13 |

| 80 | 128 | ≤0.60 | 0.10 | ≤0.16 |

| 90 | 145 | ≤0.70 | 0.11 | ≤0.18 |

| 100 | 155 | ≤0.75 | 0.12 | ≤0.20 |

| 112 | 175 | ≤0.85 | 0.13 | ≤0.22 |

5. Physical Property

| Temper | Longitudinal tensile properties at room temperature. | ||

|

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) A | |

| Not less than | |||

| T5 | 120 | 80 | 8 |

| T6 | 160 | 110 | 8 |